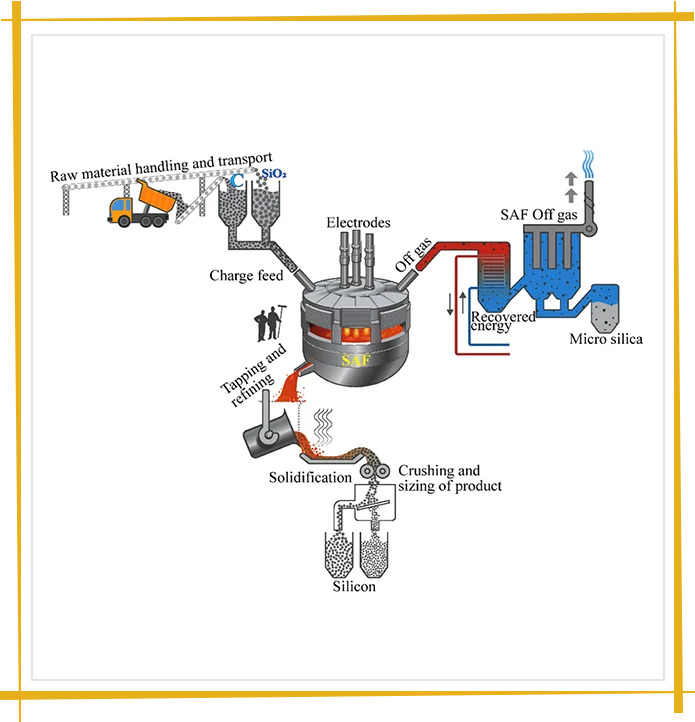

Ferro Silicon is produced in Submerged Arc Furnaces (SAF), where raw materials are melted at high temperatures to form an alloy of iron (Fe) and silicon (Si). The key ingredients include:

During production, Micro Silica (also called Silica Fume) is released as ultra-fine dust. It is collected in the Gas Cleaning Plant (GCP) and widely used in concrete, refractories, and other high-performance materials for added strength and durability.

This process ensures a high-quality Ferro Silicon alloy used in steelmaking, foundries, and various industrial applications.

We only use the best Quartz, Met Coke, Mill Scale, Electrode Paste etc.

Well equipped Laboratory and all testing as per BIS standards

We use state of the art Gas Cleaning Plant and water recycling systems

We use state of the art tech in our plant

Our electricity mainly comes from Dams in Bhutan-Hydro Power

We supply major steel plants & foundries in India

We only use the best Quartz, Met Coke, Mill Scale, Electrode Paste etc.

Well equipped Laboratory and all testing as per BIS standards

We use state of the art Gas Cleaning Plant and water recycling systems

We use state of the art tech in our plant

Our electricity mainly comes from Dams in Bhutan-Hydro Power

We supply major steel plants & foundries in India

Ugen Ferro Alloys Pvt Ltd operates an 18 MVA Submerged Arc Furnace, equipped with an Automated Raw Material Handling System and a Gas Cleaning Plant for efficient and environmentally friendly production.

In a market flooded with manufacturers, Ugen Ferro Alloys stands out with its premium-quality Bhutanese-origin Ferro Silicon. Our commitment to excellence has made us the preferred supplier for leading steel giants like SAIL, Tata Steel, and Vedanta Group, as well as major foundry hubs across Mandi-Gobindgarh, Jalandhar-Ludhiana, Pune-Kolhapur, Howrah (Kolkata), and Faridabad.

Our customers trust us because we consistently deliver Ferro Silicon that meets the highest quality standards. Whether it's for large steel plants or specialized foundries, Ugen Ferro Alloys is the first choice for those who value quality over price.

We rely on Bhutan’s abundant Green Hydro

Power to produce our Ferro

Silicon