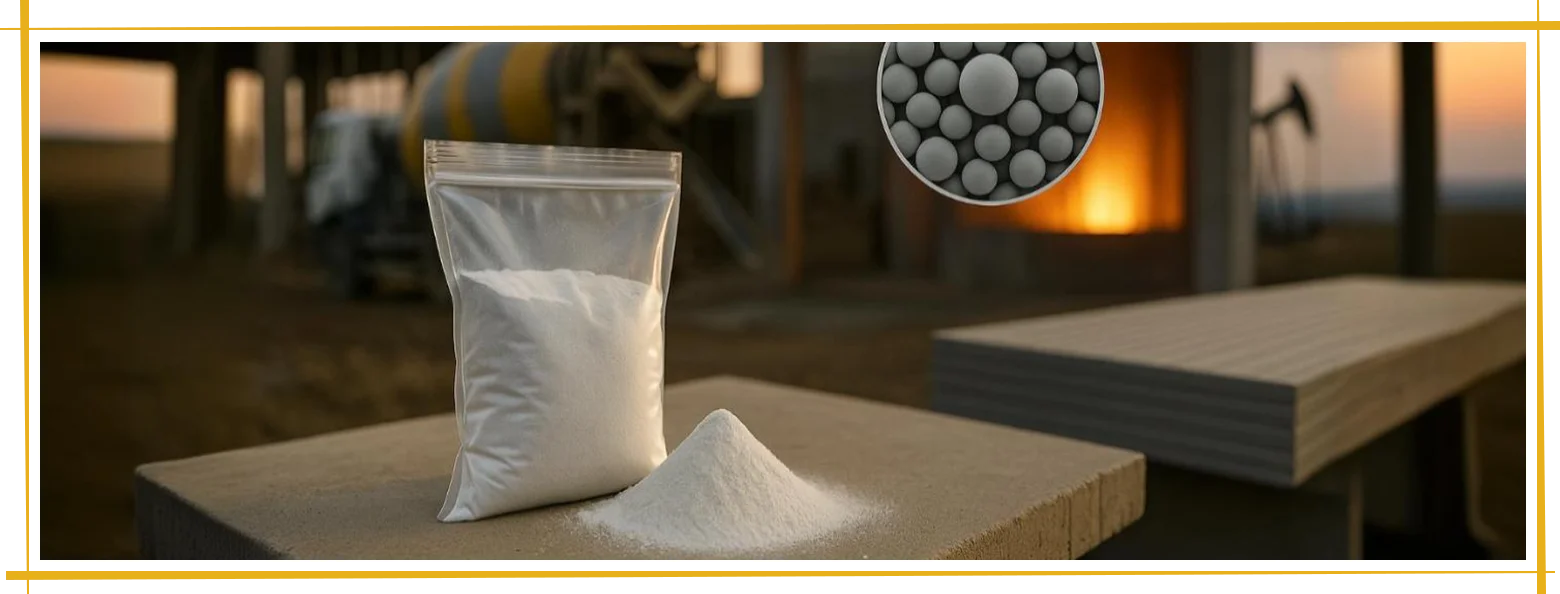

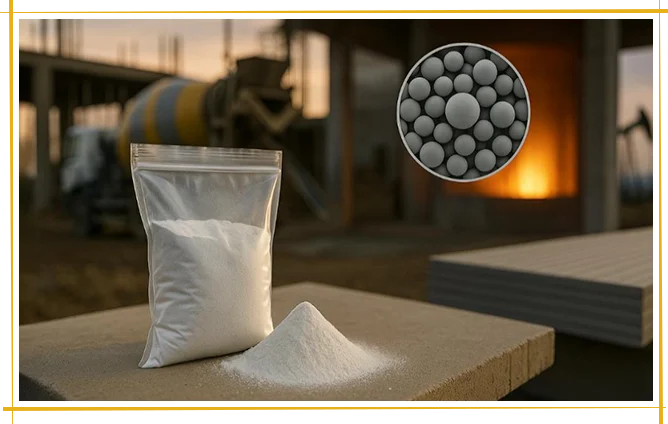

Silica fume, also known as microsilica, is a byproduct of silicon and ferrosilicon alloy production. It consists of ultrafine, spherical particles of silicon dioxide (SiO₂), typically less than 1 micron in diameter. This unique composition makes it a highly effective pozzolanic material, widely used to enhance the properties of concrete and other cementitious products.

Silica fume, also known as microsilica, is a byproduct of silicon and ferrosilicon alloy production. It consists of ultrafine, spherical particles of silicon dioxide (SiO₂), typically less than 1 micron in diameter. This unique composition makes it a highly effective pozzolanic material, widely used to enhance the properties of concrete and other cementitious products.

Silica fume is utilized across various sectors, including:

At Ugen Ferro Alloys Pvt Ltd, we are committed to providing high-quality silica fume to meet the diverse needs of our clients. Our product ensures improved performance, strength, and durability in your concrete applications. Partner with us to experience the benefits of superior materials tailored to your specific requirements.

Click to download the detailed product datasheet OR MSDS (Material Safety Datasheet) with technical specifications, features, and other important information in PDF format.

| COMPOSITION | PERCENTAGE |

|---|---|

| BULK DENSITY (kg/m3) | 700-800 kg/m3 |

| H2O | 0.50 |

| LOI | >0.90 % |

| SiO2 | 85 %+ |

| Al2O3 | 0.80 %+ |

| Fe2O3 | 2.50 %+ |

| CaO | 1.29 % |

| MgO | 0.75 % |

| Alkalies as Na2O | - |